In the fast-paced world of modern business, efficiency is the key to success. Every organization, regardless of its size or industry, strives to streamline its operations, reduce costs, and enhance productivity. One powerful tool that has emerged to address these goals is the Material Management System (MMS).

In this comprehensive guide, we’ll delve into the world of Material Management Systems and explore how they can revolutionize your business operations. So Let’s Uncover the secrets to optimizing your Business Operations with this Automated System.

Before we Begin, Consider a Live Example of How This Software Can Be beneficial for your Industry too …

Company XYZ, a manufacturing firm, faced challenges in monitoring its vast inventory and coordinating materials across multiple production sites. They implemented an MMS, and the results were remarkable. Not only did they reduce excess inventory, but they also improved on-time delivery rates, reduced procurement lead times, and achieved significant cost savings. With real-time visibility into their material movements, Company XYZ transformed their operations and gained a competitive edge in their industry.

Do you wish for the Same Results? .. Read On to Get a Complete Understanding of Material Management Software and its Remarkable Benefits.

Understanding the Basics: Material Management System Explained

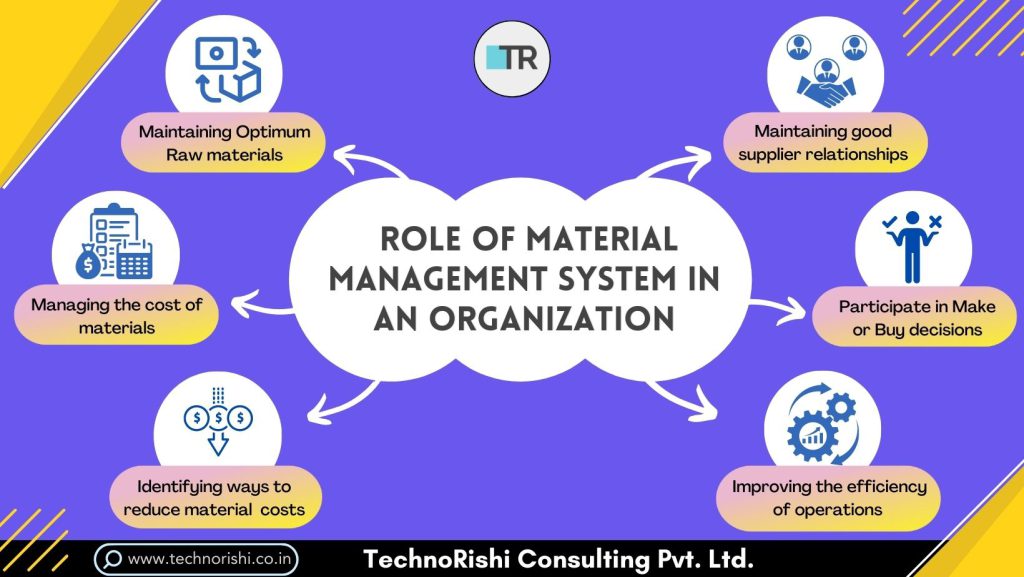

At its core, a Material Management Software is a solution designed to handle the entire lifecycle of materials within an organization. From procurement and inventory management to distribution and disposal, an MMS offers a centralized platform to oversee, control, and optimize these critical processes. It Automates end-to-end Material Gate Pass (RGP & NRGP) Processes with Workflow as per your Business Need.

➡️ To know in Details About Other Available Systems to manage your Business Operations, Click here…

Also, By providing real-time visibility into material usage and availability, businesses can make informed decisions, eliminate waste, and ensure resources are allocated where they’re needed most.

Key Benefits of Implementing Material Management Solutions for Your Organization

Streamlined Procurement: An MMS facilitates seamless procurement by automating requisitions, purchase orders, and vendor management. This eliminates manual errors, reduces lead times, and ensures timely availability of materials.

Efficient Inventory Management: Say goodbye to overstocking or stockouts. An MMS offers accurate demand forecasting, stock tracking, and automated reorder points, allowing you to maintain optimal inventory levels and minimize carrying costs.

Enhanced Traceability: With strict regulations and quality control requirements, traceability is paramount. An MMS provides a detailed audit trail of every material movement, ensuring compliance and swift recalls if necessary.

Cost Control and Savings: By optimizing inventory levels, reducing wastage, and negotiating favorable terms with suppliers, an MMS contributes to significant cost savings over time.

Streamlined Workflows: Manual data entry and paperwork are prone to errors and delays. An MMS automates workflows, such as approvals and notifications, ensuring tasks are completed efficiently.

Real-time Analytics: Make data-driven decisions with real-time insights into material usage, trends, and supplier performance. Visual dashboards and reports empower you to take proactive actions.

Sustainable Practices: An MMS enables sustainable practices by minimizing waste, promoting responsible sourcing, and supporting recycling and reuse initiatives.

It is to be noted that Before Implementing MMS Into your Operation, Your Key Responsible Persons and Managers should Consider the following Important Pointers to get the best Possible Outcomes for your Industry.

Key Pointers to be Noted Before Implementing Material Management System across your Organization

1.Assessment and Planning: Begin by assessing your current material management processes and identifying pain points. Create a comprehensive plan outlining the desired outcomes and benefits of implementing an MMS.

2. Vendor Selection: Research and choose a reputable MMS vendor that aligns with your business requirements. Consider factors such as scalability, integration capabilities, and customer support.

3. Data Migration: Smoothly transition your existing material data to the new system. Ensure accurate data entry and validation to avoid discrepancies.

4. Training and Adoption: Train your staff to effectively use the MMS. Highlight its features, benefits, and how it integrates into their daily tasks. Encourage user adoption and provide ongoing support.

5. Integration: Integrate the MMS with your existing systems, such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) platforms, to create a unified ecosystem.

CONCLUSION

Revolutionize Your Business Operations with MMS

In a world where time is money, a Material Gate Pass Management Software emerges as a game-changer for businesses seeking operational excellence. By optimizing procurement, inventory, and distribution processes, an MMS not only enhances efficiency but also drives cost savings and sustainability. As you embark on your journey to implement an MMS, remember that the key lies in careful planning, robust integration, and a commitment to continuous improvement. Embrace the power of technology to elevate your business operations and pave the way for a more prosperous future.

Want a Live Explanation of how this Automated System works for Your Business?